.jpg)

.jpg)

.jpg)

.jpg)

HPL

Compact laminates

Specialty laminates

Exclusive surfaces

Solid surfaces

Our commitment to quality begins with the selection of premium raw materials. We use sustainably sourced kraft paper, decorative papers, and high-grade resins to create laminates that are not only durable but also environmentally responsible. Our processes ensure minimal environmental impact, leveraging post-consumer recycled content and eco-friendly manufacturing technologies.

This dedication to sustainability and quality guarantees surfaces that meet the highest global standards, offering unmatched performance and design versatility for modern spaces.

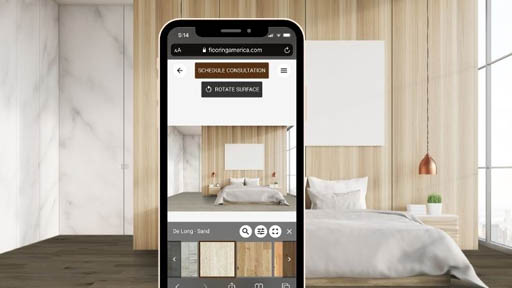

Enter the Stylam world with the Virtual Design Studio. Implement your ideas and visions flexibly and digitally.

Visualise your ideas now

Here you will find downloads for all interior fittings, floor coverings and construction products at a glance.

Find out more

Our team will review your application and get back to you if your profile matches our requirements.